A short History of Kretztechnik AG, Zipf, Austria

Dr. Joseph Woo

Kretztechnik AG, an Austrian enterprise, was founded in 1947 by engineer Dr. Paul Kretz at Zipf, Austria as a small manufacturer of resistance-welded wired goods which included potato baskets, milk bottle carriers and glass balloon baskets. There was a good market for these products after the second World war.

In 1953, with his knowledge in engineering, foresight and a desire to go after more sophistication, Paul Kretz acquired a small company developing ultrasonic equipment for material testing. Soon Kretztechnik became a strong developer of non-destructive ultrasonic metal flaw-detecting equipment, including automated systems for rails and steel bar castings, and sharing the market with companies from Germany, France and Britain.

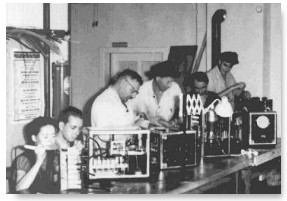

The company very quickly specialized itself in the development and manufacturing of ultrasonic systems adapted for human medical diagnosis. In the mid 1950s diagnostic A-scopes for ophthalmologic and neurologic applications were launched, the equipment being modified from the flaw-detector line. There was at that time only a small number of reports on the use of ultrasound as a diagnostic tool from the United States and Europe. (One may also recall that Austrian doctor Karl Dussik at the University of Vienna was widely considered as the first physician to have employed ultrasonics in medical (neurological) diagnosis in the mid 1940s).

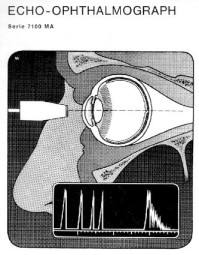

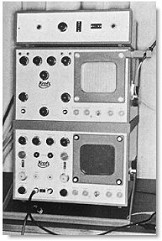

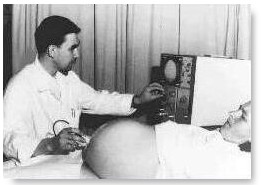

The Model 1000 (as seen in pictures above and below) was the first ophthalmological scanner marketed in 1954 for medical diagnosis. This was improved into the Model 3000 produced in 1958 and the Model 6000 in 1962. The popular 4000 series (4100) could be adapted for use in ophthalmology, neurology and Obstetrics and Gynaecology and were popular. Model 7100 became available in 1963 for enhanced ophthalmological investigations, and incorporated B-mode functions (then called Scanned Intensity Modulated Ultrasonography). Dr. Karl Ossoinig in Vienna took active part in the design of the equipments. More efficient immersion B-scan devices with electromechanical guidance of the sound beam were developed. The 7900 series produced in 1966 was a more adaptive B-mode scanner and was the first commercially available ophthalmologic scanner with A- and B-mode units . The 7900S could work between a choice of a hand-guided probe or an automatic probe transport for B-scan tomography and immersion B-scanning.

The A-scan part of the 7900S signal processing was standardized and served as prototype for the 7200 MA, which was developed by Ossoinig during the late 1960's as a stand-alone standardized A-scan unit. It was clearly improved over the 7900S. The 7200 MA went into serial production in 1970; it was the only A-scan instrument available for standardized ophthalmologic echography throughout in the 1970s and early 1980s. About 500 of these units were put into use by 1980 worldwide. Some of these units are still in use today.

At one point, immersion B-scan was not popular as the B-scan information, though impressive to look at, did not add substantial diagnostic information to the standardized A-scan, and rather lacked reliability in the display of peripheral intraocular and orbital lesions. The B-scan procedure was also time-consuming. B-scans became an integral part of standardized ophthalmologic echography again only after about 1972.Doppler devices were also produced around this time, mainly for detection of fetal cardiac pulsations. Devices for neurology were also popular on the market. The company also participated actively in medical fairs and exhibitions in Europe, including countries such as the Soviet Union.

The A-scope (the 4100 series) was used by Dr. Alfred Kratochwil in Vienna to localize the placenta. The first two-dimensional unit, the bi-stable compound scanner (modified from the same series) quickly followed in 1966 (see below) and was employed by Kratochwil in Obstetrical and Gynaecological diagnosis. Dr. Francis Weill in Besançon, France was also one of the chief collaborators with the company which had constantly received input from the medical community to improve on their equipment design. Other gynaecologists pioneering in the application of ultrasonography such as Georges Boog at Strasbourg, France, Alberto Zacutti and C A Brugnoli at La Spezia, Italy, Parache Hernandez at Madrid, Spain and Paavo Pystynen at Oulu, Finland also started with Kretztechnik equipment.

The world's first switching (stepped) multi element transducer for the eye was introduced in 1964 with design and collaboration from Dr. Werner Buschmann in East Berlin. (It was only several years later that linear stepped transducer arrays were conceived by Nicolaas Bom in the Netherlands in 1971). Buschmann's transducer was adapted for use in the 7900 models. However, it never became very functional in a clinical setting and did not go into serial production. The idea of transducer arrays as scanning devices was subsequently not actively pursued at Kretztechnik, rather much research was devoted to the fabrication of mechanical (rotary) sector scanheads (see below).

In 1965 Carl Kretz joined his uncle Paul as Head of the Research Department, then working on semi-conductor technology pertaining to non-destructive testing. Carl was born in 1932 in Vienna. He completed studies of electro-technology and field tele-communications technology at the Technical University in Vienna and graduated in 1960. After finishing his study he continued to work at the institute of the university. He also worked as an research and development engineer with ELIN in Austria and then with Landis & Gyr in Switzerland, where he was responsible for developing electronic equipment for automatic product monitoring.

Under Carl Kretz's directions, the first two-dimensional B-scan was produced at Kretztechnik in 1966. This was an evolution of an earlier ophalmological design the MG 4100, combined with a B-mode display and scanner gantry (see above, Kratochwil), and later named the Combison 1. The Combison 2, a more elaborate machine, was produced in 1974. These were the start of the Combison series.

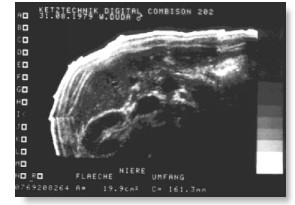

In 1975 the grey-scale Combison 200 was produced which set an European standard in grey scale B-scan image and technology. The required scan converters were produced in the Kretz factory to overcome the difference in the number of scan lines in the television monitors used in the United States of America and Europe. Subsequent to this development many manufacturers of ultrasound equipment made use of this technology. The Combison 200 soon evolved into the Combison 202 (pictured below).

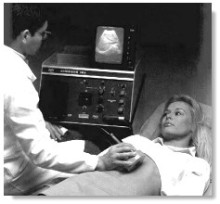

Through Carl Kretz's dedication and foresight, 1977 saw the production of the Combison 100, a real-time mechanical sector scanner for the abdomen and other parts of the body. It had a unique and large probe housing 5 transducers rotating around the axis of the probe handle. The 'rotating' mechanism was initially chosen because the angular velocity was constant, without a peaking velocity in the center of the images as in oscillating designs. A great deal of ingenuity went into the fabrication of the motors, coupling material and fluids, and the electronics which dealt with stray soundwaves and reverberations from coupling membranes and fluid interfaces.

Though the probe was quite heavy to hold in the hand, the scanner was welcomed by the ultrasound community because of the very good image it produced and the wide near-field that was not found in other hand-held mechanical sector transducers. It was well-suited for use in abdominal and Obstetrical scanning. A number of important earlier papers on fetal anomlies and the use of the fetal femur length were published using the Combison 100. The equipment continued to evolve into the Combison 100-5 and Combison 111. The Combison 202 meanwhile also incoporated real-time scanning capabilities with technology migrated from the Combison 111 series. It is worthy of note that the research, fabrication of individual parts and manufacturing of the scanners were all performed at the Austrian factory premises.

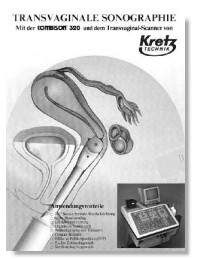

The Combison 310 followed in 1982 with both mechanical sector and electronic linear and sector transducers. The frequency was switchable between 3.5 and 5 MHz. The scanner was particularly geared to the private-practisioners market. Another great step followed in 1984: the legendary COMBISON 320 with a fully computerized ultrasound system, menu driven operation, user-programs and cine-loop capabilities (These were considered as novelty and advanced functions back in the early 1980s!).

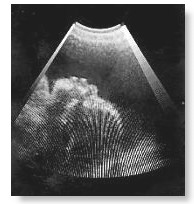

Different probes especially for endosonographic use were developed. The mechanical sector transvaginal scanning transducer in 1985 was the first of it's kind in the world market. The unique endovaginal panoramic probe had a scanning angle of 240 degrees. The transducer was developed in collaboration with fertility specialists Wilfried Feichtinger and Peter Kemeter for the purpose of transvaginal aspiration of ovarian follicles in In Vitro Fertilization procedures. The endovaginal transducers were standard attachments on the Combison 310A and 320 models. The 410 series followed later in 1993 incorporating color doppler facilities.

In 1989 Kretztechnik introduced the world's first 3-dimensional ultrasound system, COMBISON 330 at the French Radiology Congress in Paris. The second generation of 3D-ultrasound, the COMBISON 530 was launched in 1993, already delivering spatial reconstructions. The third generation 3D-ultrasound, VOLUSON 530D featured full-digital technology and interactive real-time 3D-rendering. Dr. Bernard Benoit in Nice, France, published some of the earliest, most stunning and convincing 3-D images in the mid-1990s using the VOLUSON scanners. His pictures had been responsible for drawing the attention of many to this new scanning modality. Dr. Kratochwil had continued to advise the company on designs of 3D equipment.

Even in the fabrication of the 3-D scanners, Kretztechnik carries out its own research and manufactures nearly all the parts of the scanners at the factory in Zipf, Austria, right from sophisticated circuit boards and scanner probes down to screws and transformers. In 1998 the break-through 3D technology, the "LIVE 3D" (4D) was invented. This was incoporated in the VOLUSON 730.

The work and inventiveness of Carl Kretz not only determined the success of the development of the company Kretztechnik, but also influenced tremendously the development of ultrasound equipments in general. Carl Kretz retired in 1994. He spent his retirement working with various facets of telecommunications. He was given the prestigious Ian Donald Gold Medal in Technical Development from the International Society of Ultrasound in Obstetrics and Gynecology (ISUOG) in 1999. Kretztechnik now runs a large museum at its Zipf premises exhibiting its past 50 years' inventions and development. It is "the History of Ultrasound" under the roof of a single company. Kretztechnik's achievement in the development of ultrasonography can only be described as no less than phenomenal.

From a small wired-basket ultility company, Kretztechnik AG grew to become a 3D ultrasound giant with recorded sales of approximately €150 million in 2001. Kretztechnik employs more than 400 people worldwide and operates subsidiaries in Germany, France, Switzerland and Spain. Medison, Korea, which was founded in 1885, acquired Kretztechnik AG in 1996. Medison has grown very fast over the latter half of the 1990s, and particularly benefited from the acquisition of Kretztechnik. The company also produces MRI equipment (MAGNUM 1.0T) and several models of X-ray equipment, although sales of these products are relatively small. In 2001, GE Medical Systems acquired a major shareholding in Kretztechnik AG from Medison, and Kretztechnik AG became a wholly owned subsidiary of GE Medical Systems.