"DEVELOPMENT OF ULTRASONIC SCANNING TECHNIQUES IN SCOTLAND" 1956-1979

and

"VIRTUAL REALITY" in ULTRASONIC IMAGING"

T.G.Brown 1999

A combination of two unpublished papers:

Personal Recollections by T.G. Brown

A project out of time ?

What follows has no pretensions at being a definitive account of the history of medical ultrasound. It is almost entirely autobiographical, and is simply my own recollections, blurred no doubt by the passage of time, of what happened within the group in Glasgow from 1956 until about ten years later, and then what happened when the project moved to Nuclear Enterprises in Edinburgh.

It then goes on to deal with events between 1973 and 1979 when the attempt was made within Sonicaid Ltd., at Livingston New Town, to move into what seemed the next logical stage, with the development of the "Multiplanar" three-dimensional ultrasound scanner.

Some of my friends, and notably Dugald Cameron who was an early collaborator, and now Director of Glasgow School of Art, have urged me to "tell it as it was". I was urged not to disguise the commercial pressures and circumstances which were to lead in the end - with a few brave exceptions - to the virtual disappearance of the industry in the UK, and its domination now by foreign companies.

The story is studded with near-catastrophes and some fairly heroic recoveries. Many of the vicissitudes were brought about by commercial decisions by others, unconnected with the project itself.

In this respect the medical ultrasound story is neither an unfamiliar nor an unusual one in the UK, where short-term financial gain or loss in the City seems to negate any consideration of long-term national interests, and my telling it will make little difference. However, if nothing else, it has the makings of a good yarn, with colourful characters, some comical and some near tragic situations, and something approaching a revolution in diagnostic medicine as an outcome, so I think it is worth an attempt at telling. For me the involvement with medical ultrasound came to an abrupt end in 1979 with the closure of the Sonicaid operation. I had known, intellectually, that the Sonicaid venture was something of a gamble, but was quite unprepared for the savagery of the consequences when it did not come off.

Personal background

I joined Kelvin & Hughes Ltd in Glasgow in 1951 at the age of 18 as a "technical apprentice". I had already been involved in model-making and hobby electronics for years, so that it was a kind of home-from-home.

I joined Kelvin & Hughes Ltd in Glasgow in 1951 at the age of 18 as a "technical apprentice". I had already been involved in model-making and hobby electronics for years, so that it was a kind of home-from-home.

The Company went all the way back to William Thomson, latterly Lord Kelvin, (1824-1907). It was founded by James White, Kelvin's instrument maker, and it was the vehicle though which Kelvin's inventions could be made available to others. This was during Kelvin's long tenure as Professor of Natural Philosophy at Glasgow. Following White's death, Kelvin took a controlling interest in the business, which then became Kelvin & James White Ltd., and later Kelvin Bottomley & Baird. Finally there was a merger after Hitler's war, with Henry Hughes & Sons of Barkingside, Essex, to become Kelvin & Hughes Ltd. In the front hall of the Glasgow factory there was a showcase which would have been quite in place in the Science Museum, of lacquered brass and ebonite instruments, - The first electricity meter, Kelvin's ampere balance, and so on. In the works there was an enormous range of marine, industrial, scientific and medical products, and apart from a few plating processes involving cyanide, virtually everything was done on site. Innovation was very actively encouraged, and it was a great place for a young engineer to cut his teeth.

About the time I joined, Smiths Industries had acquired a controlling interest, and over the next fifteen years or so took over completely, with various changes of name, and finally closed down the Glasgow operation altogether in 1967.

I first became involved in medical Ultrasonics in the second half of 1956, at the age of 23, having not long finished a five-year "technical apprenticeship" with the Company. Prior to that I had been attending Allan Glen's School in Glasgow, which in those days was a notable 'feeder' for the science faculties of the local universities.

I had managed to get together enough Scottish "Highers" for entry into a university course. However by the age of 17 I'd had enough of schooling for my tastes, though I still didn't really know what I wanted to do with my life.

I'd had a hobby interest in model-making, radios and the valve-based electronics of the time for some years. This had first developed when we lived in an isolated little house in the country to the North of Glasgow during and after the war.

Thereafter, as a member the Allan Glen's Air Training Corps squadron, I had re-built a gyro-magnetic compass originally from a Stirling Bomber, and "borrowed" during a summer camp at RAF Kinloss. This and other things alerted some of the teachers to a certain aptitude for this sort of thing on my part, and one of them - a Mr Sutherland to whom I owe a good deal though I guess he never really realised what he'd started - arranged for me to visit Kelvin & Hughes one evening to meet the Chief Engineer, the late Mr Peter Turner, then an "AMIEE".

Peter, who died in the early 'nineties, was an Englishman in a foreign land, and an eccentric one at that. He appeared that evening out of the Glasgow murk on his motorbike, and in his leathers, and took me inside. For me it was like wandering into a kind of intellectual 'Aladdin's Cave', and within half an hour I had made up my mind that this was for me.

At the beginning of April 1951 (mercifully not the 1st), but just a few days before my 18th birthday, I joined as a "Technical Apprentice" which was the firm's flexible term for promising youngsters who were taken on with a view to developing whatever talents they might have. Within Kelvin & Hughes I gained all sorts of experience of many different aspects of electronic and instrumentation engineering. I felt Kelvin's influence was still there, and innovation was really part of his legacy.

As part of my 'understanding' with Peter Turner I was also to study part-time for professional engineering qualifications, aiming at membership of the (British) Institution of Electrical Engineers.

About 2 years into the apprenticeship I became involved in ultrasound used for non-destructive testing of materials, under the late Alex Rankin, who was a pioneer in the use of these techniques.

Rankin was a metallurgist, and an enthusiast, and was running a very small 'applications research' unit, which was really an adjunct to the Sales organisation. His job was to develop the market for ultrasonic 'Flaw Detectors' as they were called, by assisting with the physics and the development of special transducers and other hardware to meet customer's problems.

Alex had a particular problem with Babcock & Wilcox, where the Head of Engineering, a Dr. Harris, nurtured the dream of using ultrasound as an alternative to 100% radiography of welded pressure vessels for the Process, and emergent Nuclear Industries. This involved finding some way of providing a permanent, reliable record of echo signals received from the weld areas, during a mechanised automatic 'scan' of the weld. There were formidable practical problems involved, and even today such techniques are only feasible in strictly limited circumstances, but of course we did not know then just how difficult it would be.

Alex did not feel he was getting the support the work deserved from the main ultrasound R & D department located in the factory in Barkingside outside London. I was still an apprentice and not costing very much. Having cut my teeth on other electronic projects within the company, I was more than keen when the suggestion was made that I be put on temporary attachment of his 'department', which at that time was no more than a couple of other people working in a cramped converted air-raid shelter in the back yard of the factory.

With all the benefits of youthful inexperience and enthusiasm I plunged in. At once we ran into the formidable practical problems, mostly associated with the hostile electrical environment in a welding shop, and the unpredictable acoustic contact between our transducers and the rough surfaces of the vessels.

I ended up developing quite an ambitious system which would select for recording only echoes from particular regions of the test piece, by means of electronic time 'gating'. I also found a way of stabilising the overall sensitivity of the system by selecting a reference echo from the test piece boundary, and using it indirectly to control the overall sensitivity. It sounds simple, but in practice it was quite difficult. However I got a prototype system working really quite well, and the company applied for patents.

Alex went round the country, somewhat prematurely selling automatic testing systems based on these techniques, and unknowingly building up a legacy of trouble for the future.

I had enough modesty to be a bit diffident about the standard of the electronic design, though I realise with hindsight that it was not any worse than most. So I did not argue when it was proposed that the whole project be shipped down from Glasgow to the main R & D operation in Barkingside, to be redesigned "properly'".

In fact the people there never did succeed in making a developed version of the whole system, which worked even as well as the prototype, though in time bits of it did pass into general use "in the trade". However the degree of sensitivity stabilisation performance provided by the prototype was never to my knowledge achieved again.

In the meantime I got a pat on the head and the company proposed that I should go to University, sponsored by them. I did so, and having been denied my first choice of Medicine, I chose instead a course in Applied Physics. In the end this turned out to be too much for my limited mathematical capabilities. This was exacerbated by being 'excused' the first year of the course because of my previous part-time studies, too much snooker, and too much time spent with my girlfriend and later fiancée who was a student nurse in the city's Western Infirmary.

I had really bitten off much more than I could chew, and the long and short of it was that a year later I had to crawl back to Peter Turner, and ask for my old job back. I had not experienced the bitter taste of failure before, and I think it was this uncomfortable episode which not only set the scene for me, and my involvement in medical ultrasonics, but made it so imperative that I should not fail again.

The story, or at least the essence and flavour of the story, is captured by Robert Reid in his book 'My Children, My Children' (Pub British Broadcasting Corporation 1977, ISBN 0 563 12857 7). In pages 37 to 59 "Experiment", the 'flavour' is definitely there, though there are some technical and historical inaccuracies in the account, which I think was mainly written from Donald's recollections. These are mostly to do with the order in which things happened. As I remember it, things went like this:-

I was still in disgrace, working away in a corner of the lab on a lowly project - a little device for measuring smoke density in factory chimneys. (We never did sell them very well to factories, but did a quite a good trade with crematoria for a while.) One afternoon some of my friends who had been installing an experimental shadowless lamp in an operating theatre in the Western Infirmary mentioned that 'the doctor' there - Professor Donald - was using an ultrasonic flaw detector on people.

Not knowing any better, I looked him up in the book, and telephoned him that evening at Western 5050. He sounded rather posh to this young native Glaswegian, but he was friendly and very courteous, but told me that he had all the technical help he needed from Ron Greer, of Dr. John Lenihan's 'Regional Medical Physics Department'. However I was welcome to come and see what he was doing.

This "paralysis" problem was the reason for the comical arrangement which greeted me when I first saw 'the apparatus', of an open-ended glass cylinder, large carafe of water, and a large jar of "Vaseline".

Ever the practical improviser, and realising that he had somehow to allow the amplifier to de-saturate after being clobbered by the transmitter pulse, Donald greased one end of the glass cylinder with Vaseline, stuck it on the patient's abdomen, filled it up to the brim with water, and placed the ultrasound probe in the end, directed through the water into the patient.

The amplifier then had time to de-saturate while the sound pulse was travelling down the water column, and Donald was able to see echoes coming back from inside the abdomen when the sound pulse reached it. The next practical problem, in which the Professor was not always so successful, was to get the water back into the jug without soaking the patient or himself.

What to me was striking, despite the comedy, was that was obviously information there, if only we could make sense of it.

I went back and telephoned Alex Rankin, who was by then back in the Barkingside labs, embroiled in the automatic scanning fracas. Being the man he was, never allowing paperwork to get in the way of progress, it was only a few days before a brand new MkIV Flaw Detector arrived at Glasgow Central Station, sans paperwork, marked "To be called for by Mr Tom Brown".

I didn't drive in those days, but I got that brute of an instrument out of the station and into a taxi, up to the Western Infirmary, then onto a patient cart, and finally up to Wards D9/10, which was Donald's Gynaecology Unit.

The MKIV was also a double-transducer machine, but when used with a decent double-transducer 'probe' the results were strikingly better than anything Donald had ever seen before, I was 'in' as it were, and Dr. Lenihan's man had to take a back seat.

We were to pay a heavy price in years to come for neglecting the courtesies towards Dr Lenihan and his people, but then I was far too gauche a young man to realise it, and it was not in Donald's nature to worry over much.

The other thing I was able to do at that time was to dig up an old, but still functional 'Cossor' oscilloscope camera with which to record the traces on the screen on 35mm film. This seems to have been a much more significant addition to the system, at least so far as Donald was concerned, than I realised at the time, though on my part it was just another bit of scrounging, at which I was to become rather adept.

From the A-scope experiments it appeared that there actually was a lot of echo "data" being returned from inside the patient. Whether this was all really going to lead to useful "information" was of course not known, but even with the A-scope we were already able to recognise fluid-filled cysts, and to discriminate reasonably confidently between these and solid masses, and between either and the 'normal' bowel echoes.

Serendipity again

I realised recently that Serendipity was still playing her generous part at that stage, since the available sensitivity of the system was such that we could get echoes from the far walls of cysts without difficulty, but not from the far sides of fibroids and other solid masses.

Had the sensitivity of the instrument or the probes been just a little greater, I now suspect that the confidence with which we made these differential diagnoses might have been a great deal less, and that in turn could have a disproportionately negative impact on the enthusiasm, - which was just about all we had to sustain us at that time, and was sorely tried by the scepticism of others.

To me the A-scope display, adequate as it was for industrial testing, did not seem to me to be well suited to the medical application.

In the industrial case the correct choice of transducer system, and the optimum choice of acoustic wavelength in relation to the grain structure of the metal, one could expect to see 'flaws' as more-or-less discrete, stationary, and reasonably unambiguous 'blips' somewhere between the 'transmission signal complex' and the 'boundary echo'.

In the medical case there were usually many echoes to be seen simultaneously, and these moved around and fluctuated wildly both in number and in size, with the slightest movement of the probe or the patient. Some changes seemed to be related to heart rate, others to respiration, and others to peristalsis, - or to nothing-very-much-in-particular.

The general impression I had was there was a lot or raw data present, but that although we could extract some of it as useful intelligence, particularly in a few easily recognised situations, there was far more there than we could readily interpret.

In other words - and it is a theme I was to come back to time-and-time again in the rest of my career - there was a serious mismatch between the manner in which the data was being presented, and the perceptual faculties of the observer who had to utilise it.

After the lapse of forty-odd years I cannot now remember exactly how, and in what sequence of steps, the original cross-sectional scanning and display system came to be conceived. However there are some recollections which are quite firm.

Firstly, I have always been a bit of a "dreamer", and things which I develop usually go through a kind of internal mental gestation. There was a period after the Mk IV was in Donald's hands when I was doing quite a lot of thinking and dreaming. There were clearly lots of echoes coming from lots of places within the body and what we needed was some automatic means of making sense of them by 'plotting' where they came from.

When the ideas had gelled sufficiently, I found it a bit difficult to fire either Donald or John MacVicar with my 'dream' ; or even make them understand it. I remember thinking that it would be much easier just to build the thing and show them.

While this may seem ungenerous, but it is not really a criticism. Donald and MacVicar had, after all, only recently started into exploring the medical utility of quite an expensive, sophisticated and highly-developed electronic package which had just come, fortuitously, into their hands.

They had by no means exhausted its possibilities, but here was a young impatient who wanted, without any tangible resources, to rush off and radically change everything.

However, Donald did make an approach to the company via one of the London-based sales people, Ted Smith, who he had come to know through a mutual and compelling interest in yachting. I received a courtesy copy of this letter which I held onto for years, then lost sight of, and then re-discovered recently when clearing out my papers. A copy is attached.

Within Kelvin & Hughes I did already have the advantage of something of a track record, partly from my work on industrial ultrasound and partly from certain other 'rabbits' which I had produced out of other technological hats. Without this I do not think I would ever have been taken seriously.

Peter Turner was still my boss, but there was a limit to what he could authorise on his own account. The organisation of the company consisted of three manufacturing locations, several trading divisions and an administrative HQ at Wembley in London.

Sitting on top of the pile and resident in Wembley was the Chairman, Mr. G.B.G. Potter, an autocrat, whom I did not know. His deputy was Mr. William T. Slater, resident at the Glasgow factory, but commuting weekly to London. He was Peter's immediate boss, and had a very respectable record as an innovator himself.

To Bill Slater must go a very great deal of the credit for the medical ultrasound project being allowed to happen. At times Slater almost literally hid the whole thing from Potter and the rest of the board, and fed it with such monies as he could find, almost in defiance of his colleagues.

When I first approached the company to be allowed to do this project it was via Turner and then Slater. They sent me off to see Bill Halliday at Barkingside.

Halliday was 'Chief Scientist' of Kelvin & Hughes, and responsible for all applied acoustics work within the company, a substantial part of which was covered by the Official Secrets Act. He was a gentle, cultured, humorous, intellectual, and a man of some stature in the underwater echo-location business.

Ironically for an acoustics scientist, Halliday suffered from a progressive nerve deafness condition. For years he overcame this handicap by the use of a trouser button and a bootlace. The bootlace was fixed into the button, which he then stuck in his ear. The other end went into the breast pocket of his jacket. The result? People thought it was a hearing aid, didn't mutter as they usually did, and Halliday could hear what they were saying.

I had prepared my piece for him and went though it once.

He looked blank. So I started again - more loudly - at the beginning. Half way through he put up his hand to stop me - "Stop Brown, I now appreciate the full enormity of what you are proposing".

However there was a twinkle in his eye and whatever his reservations then, and in the months to come, I got his blessing, and continuing support. In due course a memo came out from Mr. Slater to the effect that a budget of all of five hundred pounds had been allocated to the project, and Mr. Brown was authorised to spend half a day per week working with Professor Donald.

I had done some preliminary homework - the Company made marine radars. There was some similarity between what I wanted to do and an experimental 'True-Motion' radar system which was being developed as an attempt to avoid what became known as "radar-assisted collisions" at sea. These were due to something like the comical situation when two people walking towards one another, both step aside - but each of them into the other's path !

In the "true-motion" radar system, information about the ships' course and speed was fed into the display system in addition to the normal radar information coming from other ships in the vicinity and from the land masses round about.

The effect of this was to cancel out apparent movement of the land masses and any other fixed targets on the display. Instead "own ship" appeared to sail across the screen, the land masses appeared stationary, and the true course and speed of other ships was more clearly seen.

At first sight it seemed that this system could be adapted for medical ultrasonic purposes. If the patient was regarded as an 'island' and the probe regarded as the 'ship' then such a system might allow the 'ship' to travel around the 'island'. The 'island' - the patient - would remain stationary, as would echo information coming from inside, while the 'ship' - the ultrasonic probe - would appear as though it was travelling round the patient, 'painting-in' the echo patterns in their correct positions as it went.

Unfortunately it turned out that in practice the true-motion radar system was much less accurate than necessary for the medical application, and was only usable for marine purposes because mercifully the long-persistence screen faded quickly enough for 'old echoes' to have died away before the errors in the positions of new ones became too obvious. There was a fairly fundamental design problem underlying this, which was not readily susceptible to improvement, and so I was forced to develop my own system more-or-less from scratch.

It was a case of scrounging for parts wherever I could, and generally I could count on goodwill - or at least patient tolerance - on my raiding expeditions. I managed somehow - and cannot now remember how - to get hold of another rather older MKIV flaw detector which was to provide the basic transmitter, receiver and high voltage power supply for the system.

The display unit from the old Mark IIB was cannibalised to provide an extra screen, and I managed to reclaim the main electronic cabinet and power supplies of my experimental weld-testing system, which were by then lying discarded at the Barkingside R & D Department. An additional six-inch electrostatically-deflected cathode ray tube of the type used in the MKIV flaw detector was winkled out of the stores, and I had the bones of the electronic system, which I could then start to clothe with flesh.

To measure where the ultrasonic transducer (probe) was in space, I chose an 'X-Y' orthogonal measuring frame system.

This remained a fundamental difference between our approach, and in the years to follow, from the European (Kretz) and American (Physionic/Picker, etc.) systems which used "Anglepoise lamp" techniques.

It led to high 'registration' accuracy, and consequently high resolving capability. It also enabled quite acceptable accuracy to be obtained from relatively inexpensive measuring elements, such as linear and sine/cosine potentiometers.

In later machines this was unfortunately at the expense of relatively cumbersome mechanical mechanisms to support and adjust the location of the scanning plane relative to the patient with the necessary five degrees of freedom.

However the prototype was extremely crude, and the whole thing was built, using government-surplus bits, and "Mecanno" sprockets and chains, on a borrowed hospital bed table. Initially this allowed only transverse scans to be made, with the unfortunate operator - usually John MacVicar - guddling about underneath it in a most cramped and uncomfortable position, hardly conducive to good experimental technique.

Industrial Ultrasonic Testing

Shame is the spur ?

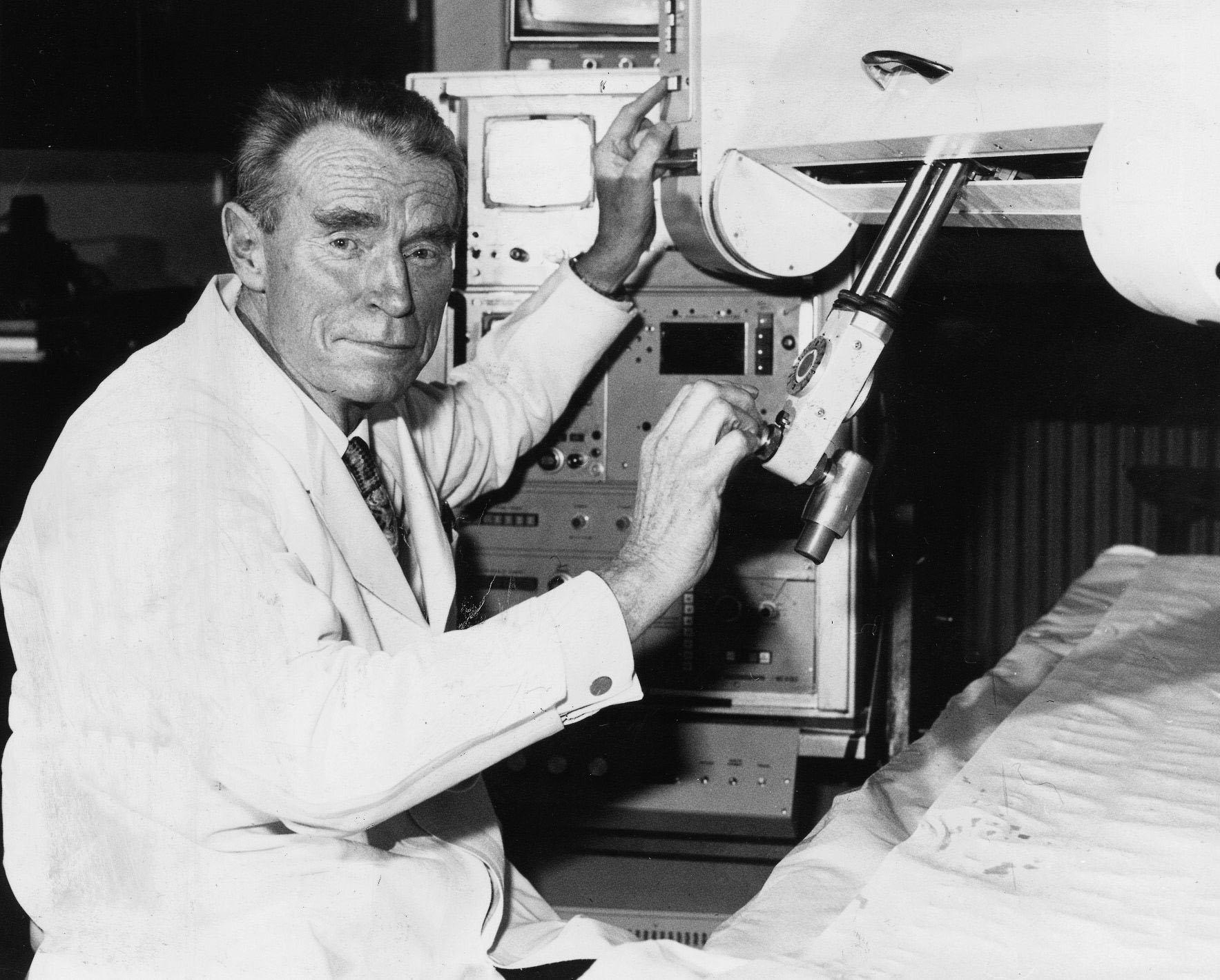

Lady Serendipity So I went along a few days later, and found him using a very much the worse-for-wear "black-crackle"- painted Kelvin & Hughes Mk IIb 'Supersonic Flaw Detector'. This ancient instrument had not even been made by Kelvin & Hughes, but was built to their designs by some other company under a Ministry of Supply manufacturing contract. It had been designed, as were most early British machines of that type, for separate transmitting and receiving (quartz) transducer operation.

This machine had been modified at the Royal Marsden Hospital before Donald got his hands on it. No doubt it was done with the best of intentions, but the "conversion" to single-transducer operation was achieved by simply connecting the output of the thousand-volt transmitter pulser more-or-less directly into the amplifier input. This caused the amplifier, never designed for such insult, to go into complete paralysis for several hundred microseconds, before staggering back into some degree of normal function.

So I went along a few days later, and found him using a very much the worse-for-wear "black-crackle"- painted Kelvin & Hughes Mk IIb 'Supersonic Flaw Detector'. This ancient instrument had not even been made by Kelvin & Hughes, but was built to their designs by some other company under a Ministry of Supply manufacturing contract. It had been designed, as were most early British machines of that type, for separate transmitting and receiving (quartz) transducer operation.

This machine had been modified at the Royal Marsden Hospital before Donald got his hands on it. No doubt it was done with the best of intentions, but the "conversion" to single-transducer operation was achieved by simply connecting the output of the thousand-volt transmitter pulser more-or-less directly into the amplifier input. This caused the amplifier, never designed for such insult, to go into complete paralysis for several hundred microseconds, before staggering back into some degree of normal function.

On the side of the angels

First success

Concept

Patronage & Vision - Bill Slater and Bill Halliday

Patronage & Vision - Bill Slater and Bill Halliday

Radar Techniques

The Bed-Table Scanner

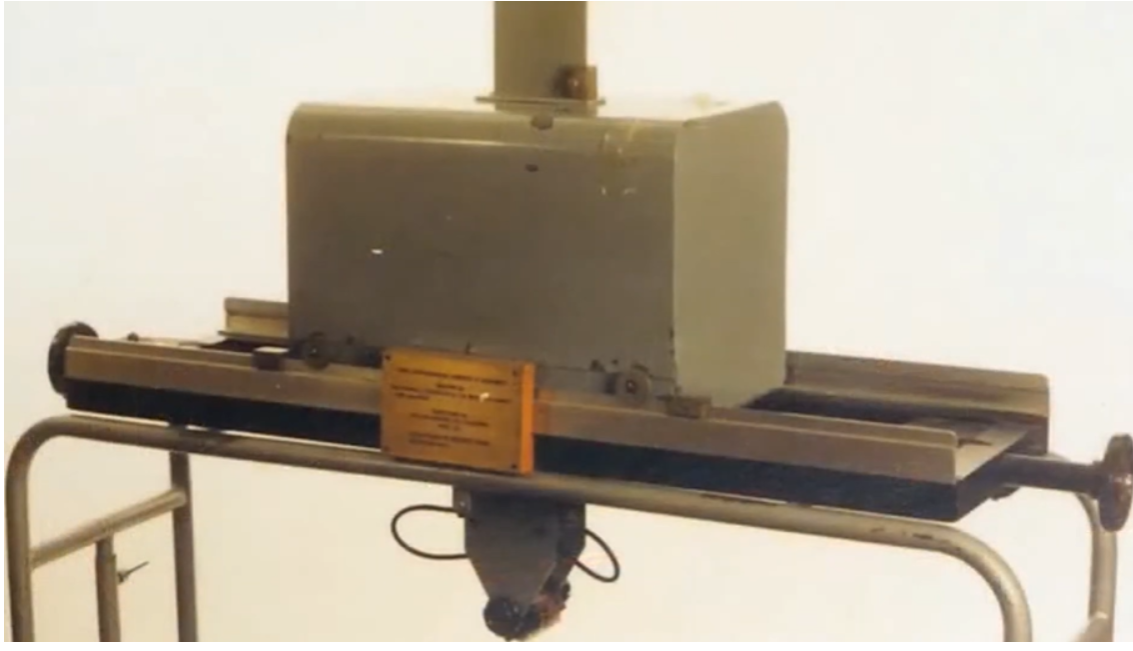

The earliest Gantry built on a hospital bed table and scopes, Mark lV and cannibalised Mark IIB.

Safety

I usually leave it to others to debate the safety of medical ultrasound. However I do have some strongly-held views formed over the forty-odd years I have been involved.

It is an unfortunate reflection on our present society that it is much easier for people to gain attention by being the bringers of bad news than it is to do the hard work of creating something positive for the general good. Hence an ongoing stream of health warnings about this, that and no doubt in the future, practically everything else. "New research has revealed" is one of the clichés of our time.

Though there are, of course many malign things about us of which we should most certainly be aware, to me the sensible use of ultrasound for diagnostic purposes is not one of them. There are good common-sense reasons for this statement, which might otherwise smack of complacency.

The first thing to recognise is that ultrasound is vibrational mechanical energy like any other sound, except that it is of a pitch - not magnitude - well above that of sound we can hear.

Thus we can choose to use a little of it, or a lot of it. If we use a great deal, we can certainly produce biological effects, including damage, For many years now physiotherapists have been and are using a lot of ultrasound, most effectively, to treat bruises and sprains etc. on sportsmen and the general public Such treatment uses many orders of magnitude more ultrasound than should be required for diagnostic purposes.

That does not mean we should not be vigilant, researching the thresholds of biological effects, particularly on the developing embryo, but it should put in perspective the exaggerated fears one sometimes hears expressed, especially when this is compared with the benefits obtained in taking the guesswork out of diagnosis.

To reduce it to a rather absurd parallel, we all know that very hot water can cause painful burns or even death. Though it might be popular with schoolboys, that doesn't mean we should avoid washing !

The other basic consideration is that ultrasound is different to particulate electromagnetic energy such as X-rays. We know for certain that electromagnetic radiation does cause damage at a cellular level, and the number of cells damaged goes up directly with the dose - i.e. the number of particles - which are received. It generally kills the affected cells, but in some cases if the damage is of a particular kind, it can allow the cell to survive, but malfunction dangerously when it reproduces itself.

We don't get ultrasound "particles" to cause this kind of damage. Most of the research into the safety of ultrasound concentrates on whether the mechanical effects it creates at high energy levels at cellular level, can lead to interference with the way cells reproduce or function. Such research is sensible, and should be continued, but so far there are quite a few generations of people walking around without any apparent ill effects whose mothers, and their mothers before them have been ultrasonically scanned during pregnancy.

For our part, from the very outset in the mid 1950's, because of concern about the possibility of biological effects, I adopted a policy of ensuring that the amount of ultrasound used should be the absolute minimum required to produce an adequate diagnostic result.

This does not mean that we thought there were biological effects at the power levels used, in view of what we knew, and what the physiotherapists were doing. It was simply what we thought would be the most responsible course to take. To achieve this the sensitivity of the whole system was controlled by reducing (attenuating) the transmitter output, whilst keeping the receiver amplifier running at maximum noise-limited sensitivity. The pulse-repetition rate was only 50 pulses per second on the MKIV, though it could easily have been increased. We chose not do so, because we considered 50 was adequate in relation to the angular resolution of the probe and the angular scanning rate being used. ( )

This philosophy was continued when our scanners went into production. Each was fitted with a calibrated attenuator, which also made it possible to make reasonable quantitative observations on the relative attenuation of different types of tissue mass.

All this contrasted sharply, I am afraid, with American practice, which seemed to be to use as much power as they could, and as high a pulse-repetition rate as they could get away with.

Technology

For the technobuffs, the electronic system, though it was novel, had the virtue of great simplicity.

It consisted, in essence, of two vacuum-tube integrator and mixer circuits, acting as vertical and horizontal timebase generators.

The vector sum of these timebases, as seen on the display, was a linear timebase vector, starting at a position on the screen corresponding to the position of the probe spindle, and moving in a direction corresponding to the direction of propagation of sound into the patient. When the timebase got to a position corresponding to the position of the probe face (with corrections because of the type of "Perspex" fronting blocks used), the transmitter was fired.

As echoes came back they were amplified in the MKIV, and then passed to a rather unusual signal processor - where art and science tended to co-exist - and then used to brightness-modulate the timebase.

Grey Scale

Much has since been made by others, years later, about the "invention" of grey-scale imaging.

The reality is that the display in the machines developed in Glasgow in the mid-1950's was a grey-scale one from the outset.

The function of the signal processor was two-fold. In the first case it provided a degree of time-domain pulse shaping, in an attempt to separate echoes arriving closely-spaced in time.

Much has since been made by others, years later, about the "invention" of grey-scale imaging.

The reality is that the display in the machines developed in Glasgow in the mid-1950's was a grey-scale one from the outset.

The function of the signal processor was two-fold. In the first case it provided a degree of time-domain pulse shaping, in an attempt to separate echoes arriving closely-spaced in time.

Secondly, and this is probably the most important function, it was to enable the display to record the very large dynamic range of signals which were received, without going into 'hard limiting' at the top end, or suppression of small echoes at the bottom end. When we say "very large" we mean at least 60 dB - that is a range of signal amplitudes of more than 100 to 1. Achievement of this was imperfect of course, but the intention was there, and in reality was reasonably well achieved. However, as will be described later, the focus at that time was as much on "spatial noise" reduction by signal integration as it was on accommodating the large dynamic range of the received signals.

Recording of the scans was by photographic integration. A time-exposure photograph was made of the display screen during the scan. The operator monitored what he was doing by observing the original A-scope screen.

Initially 'soft' 35mm film was used in a Cossor oscilloscope camera, (and I had to stay behind after each session to develop the film!) Later on we switched to the very early 'Polaroid' material which increased the convenience and the immediacy of the results, but at the expense of small-echo suppression by the 'bottom bend' of the film material characteristics. We later learned the advantages of a small amount of pre-exposure of the film.

When later we decided to use storage displays for monitoring, we went directly to half-tone Hewlett-Packard ones, and never fell into what I considered to be the American trap of using bi-stable "soot and whitewash" Tektronix displays. When the early analogue scan converters appeared, and were hailed as bringing in the grey-scale "revolution", I felt the difference in the results in the UK was significant, but hardly a "revolution". The appeal these things had was at least partly a subjective one, since because of charge-spreading on the scan converter target surface, the pictures tended to have a 'woolly' or 'fluffy' appearance which gave a comforting - though I felt rather misleadingly - 'anatomical' appearance to the results.

Compound scanning

It was recognised, from industrial practice, that with the fixed-focus transducers of the day, and even despite the huge dynamic range of signals received, the range resolution achievable is much better, probably by a factor of ten, than the resolution in azimuth.

The consequence of this is that when the sound beam is swept angularly across a point reflector, the resulting image is a thin arc, the length of which corresponds to the width of the sound beam as it passes across the target. The thickness corresponds to the range resolution.

If the measuring and display system are sufficiently accurate, and the sound beam is swept across the point target from a different position, the second arc will intersect the first.

If this process is repeated from multiple positions the intersecting arcs will develop into an "asterisk" with the centre illuminated from all directions, and therefore strongly reinforced and "sharpened" on the photographic film, while the edges of the individual arcs fade into a sort of faint penumbra.

This is directly analogous to the techniques the neurologists use to extract faint "brain-wave" signals from background noise, except that the signals and the noise are distributed in space rather than in time.

Probes

In the early days Kelvin & Hughes tended to use separate transmit and receive systems, with double-transducer probes. The advantages of this are often misunderstood.

The first is that the sensitive receiver amplifier is not 'assaulted' by the massive transmission pulse, and is therefore in a position to handle small echo returns from sources close to the probe face. Secondly, the two acoustic systems are side-by-side, so that their acoustic beam patterns progressively overlap with distance from the probe. This means that the combined sensitivity is low close to the probe face, rising to a maximum at some centimetres away. It was this characteristic which explains why swept gain ("TVG") was not high on our list of early priorities. We could get the effect of TVG simply by adjustment of the probe system geometry. There was a significant penalty in overall sensitivity, but with the poor performance of the available single-transducer probes of the day, this was offset by the other advantages. Initially quartz was used as a transducer, subsequently replaced by barium titanate.

Right at the start, I knew I had to be able to direct sound into the patient at angles off the vertical to the skin. I had not formalised it then, but we rapidly came to realise that some form of 'compound' search pattern was going to be required. The advantages of formal compound scanning were to become clear very shortly, and are spelt out in our publications. To enable off-axis scanning to be done, without distorting the patient's skin surface, I proposed to use a 'water-bag' on the probe nose. What better container could I find than a condom? Hence the picture which John Fleming has found of the very early and rather comical probe assembly (safer ultrasound?). We intended to fill the condom with an attenuative liquid to minimise reverberation, but even so reverberation was found to be so offensive that we abandoned it, and went for direct contact.

The frequency used was 2.5 MHz, corresponding to an ultrasonic wavelength of 0.6mm This was chosen partly because it was one of the standard frequencies on the Kelvin & Hughes industrial machines, and partly because it was quickly found to give a good trade-off between range and resolution, with the available technology of the day. Patents were applied for by Kelvin & Hughes prior to publication of our early results in 'Lancet' in June 1958. I was named as inventor, though commercial rights were assigned to the company. I understand that this patent, and it's foreign cases, are regarded as being extremely basic, and cover all subsequent contact scanners. However, Kelvin & Hughes were locked in a patent battle with Automation Industries, and no attempt was made to enforce these patents until they were eventually acquired by Automation about 1965.

Records

At a very early stage of the project, I realised that we would soon become swamped in photographs and that some system would have to be devised to keep track of them. The solution was an illuminated box which could be inserted between the camera and the screen, which enabled patient data and details of the main parameters of the scan, to be superimposed on the scan photograph. This also allowed for a controlled amount of pre-exposure of the film material if required. We also designed a slip-in card, with suitable 'boxes' for up to half a dozen or so scans, and the essential patient data. This card had a dual function, since it also had the Copeland-Chatterton 'Paramount' edge-punchings, and was over printed with a selection of categories, such as clinical condition, patient ID number etc., and was quite effective as the basis of our case recording system. When the scan results were recorded on Polaroid, the prints were stapled directly to the card. The margins of the edge holes could then be punched out as appropriate, so that all patients with a similar condition could be selected by passing a needle through the card pack, and shaking out the desired category. It was a simple system, but very effective, and I think contributed quite substantially to managing the clinical aspects of the project. Years afterwards I earned my living developing databases within the oil and gas industry. When I look back, I realise I built my first one, using bus-ticket technology, in the late 1950's.

Automatic Scanning

I hope I will not offend John MacVicar too much if I say I became a impatient at times with the way the scanning was being done, and poor John had to do most of it. However in all fairness the prototype bed-table machine was anything but convenient to use, and I suppose it was I who was ultimately responsible.

Nevertheless I did find it difficult to decide whether problems, or apparent inconsistencies, were due to equipment variations, or to operator-related causes.

I hope I will not offend John MacVicar too much if I say I became a impatient at times with the way the scanning was being done, and poor John had to do most of it. However in all fairness the prototype bed-table machine was anything but convenient to use, and I suppose it was I who was ultimately responsible.

Nevertheless I did find it difficult to decide whether problems, or apparent inconsistencies, were due to equipment variations, or to operator-related causes.

I had quite deliberately left off any identifying labels on the electronic controls of the equipment, so that nobody else dared to change them, and in this simple but effective way ensured that I had to be present during use, and so was quite confident about the electronic aspects of the experimental conditions. I think this probably suited Ian Donald quite well. However it was the middle 'fifties', and I was a young medically-unqualified layman, so that there was no way the late Victorian establishment of the Western Infirmary would countenance me ever laying medically-unqualified hands directly on patients - especially O & G ones.

So - if I was going to take control of the examination conditions, I was going to have to do so by some other stratagem. Whatever other contributory justifications there may have been, this was the main reason for developing the automatic scanner.

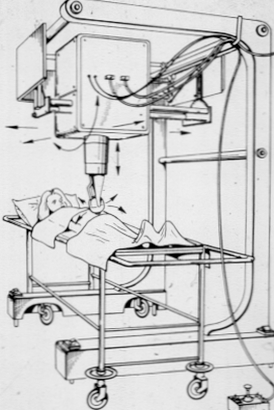

I do not think there ever has been, or ever will be, another such machine built. Rather sadly it has not had much publicity, since we decided at quite an early stage that we could not attempt to manufacture it commercially. We would instead go for a hand-operated machine based on the second prototype hand scanner, built for Dr. Sunden of Lund, Sweden. However it was a lovely machine. The 'business end' of the automatic scanner consisted of a probe holder in a 'silver ball' - which looked a little like the kind of soap dispenser once commonplace in public toilets. This was mounted on a vertical, telescoping motor-driven column, such that it moved up and down to keep the probe face in contact with the patient's skin . It too was shiny chromium plate. A pressure sensing switch ensured that it maintained contact with the skin, but with minimal pressure.

The silver ball rocked to-and-fro on an axle, driven by a system of cranks and connecting rods. Slightly indelicate looking soft plastic "nipples" on either side of the ball touched the skin when the probe axis had moved about 30 degrees to the perpendicular to it, and - almost as sensitive as the real thing - caused the rotary motion to stop and then reverse its direction.

Each time the nipple touched the patient's skin, another set of relays and motors were activated to inch the vertical column sideways. This, when combined with the compensating up/down motion to keep the probe in contact with the skin, caused about a 15mm tangential displacement between successive "sweeps" of the rotating probe.

In this way the probe gradually 'walked' across the abdominal surface, rocking to-and-fro as it went, carrying out what was actually quite a thorough, and highly-consistent compound scan.

Of course it was not quite as simple as that. To enable it to work properly on the steep flanks of the often rotund ladies being examined, an automatic changeover mechanism operated at about the 45 degree point on either side of the vertical, so that the horizontal drive then controlled the pressure, and the vertical drive did the 'inching'. The distance the machine 'inched' each time was regulated by a profiled cam system, so that it remained constant, irrespective of the average angle of the probe to the vertical. Nowadays it would all be done by microprocessor, but then it had to depend on cams, switches and relays - and I guess it was the sort of thing which would have delighted Heath Robinson.

There was a 'joystick' controller in a box on the end of a cable, by means of which the operator could position the probe for the start of the scan, but when he had done so, his task was over. He simply pressed the 'Auto' button, and the machine did the rest.

When it had finished, (about 90 seconds later on a big lady), it would switch itself off, and then ring a bell to summon him back. It may seem unlikely, but such was the confidence which developed in the machine, and the pressures of nicotine addition, that the bell became a necessity.

3-D scanning possibilities

The mechanism supporting the 'silver ball', and generating the up/down motion was itself mounted on a turntable within the main enclosure of the machine. Though it was intended to make 3-D scanning possible, the facility was only used in practice to rotate the scanning plane through 90 degrees. from transverse to longitudinal, and back. In this way one could do longitudinal and transverse scans equally conveniently.

There were also facilities for tilting the scanning plane, or arranging the patient couch at right angles, so that the full range of scanning plane options was available. The machine gantry was an over-bed one, so that if necessary sick patients did not require to be moved from their own beds.

However the thinking behind the machine did go a bit further than this. The rotating turntable arrangement was intended to allow for compound scanning sweeps out of the conventional scanning 'plane'. In other words, the machine could scan in the third dimension, and of course, had translational measured movement also in three axes. So, it was in reality a three dimensional scanner, built in the late 1950's.

The plan was ultimately to construct a display system which would make such three-dimensional scanning a practically-useful facility. This intention seemed to me to follow quite logically from the philosophy of 'compound' scanning. If the resolution-enhancement, and the artefact-rejecting properties of a compound scan, associated with some form of signal-integrating display system, were to be taken to their logical conclusion, then that had to include extending the compounding into the third, orthogonal plane.

I tried to explain all this in my article on "Ultrasonics" some years later (1967), but I do not know to what extent I succeeded. In the event several things happened to frustrate this development. Firstly, as the acoustic systems improved, attention focused more and more on non-spectacular echo formation from the macro structure of the tissues, and away from "specular" tissue boundary imaging. Secondly, those of us involved within Kelvin & Hughes (by then part of Smiths Industries) became heavily involved in emergency 'rescue' activities to recover the legacy of Alex Rankin's enthusiastic selling of my automatic scanning adventure as described later. Though a prototype three-dimensional display system was partially developed by John Fleming, the 'coup de grace' was closure of the Glasgow factory in 1967, and transfer of the medical scanning activity to Nuclear Enterprises Ltd of Edinburgh, who were just not interested in this direction of development.

Practical pay-off from automatic scanning

The practical significance of the automatic scanner was that it did more-or-less completely remove the operator dependence of the results during the critical period from about 1959 through to 1965, during which Donald was exploring and developing the clinical basis of the technique. Thereafter it was phased out in favour of the first of the hand-operated 'Diasonograph' machines, though it did go on to do further service with Ellis Barnet and Pat Morley in the X-ray Dept within the Glasgow Western Infirmary, on non O & G applications.

Some of the original engineering drawings of this machine are preserved, as is the machine itself at the Huntarian Museum in Glasgow. However documentation of the extremely complex network of relays, switches, clutches, motors etc., was less than perfect, and keeping the thing working was a rather bitter chalice, gratefully passed on from one pair of hands to another, firstly from myself to a very gifted man, Clive Ross, now somewhere in the USA, and then to John Fleming.

Dr Sunden's Machine

About 1958/1959 a young Swedish obstetrician, Bertil Sunden, visited Donald looking for a subject for his MD thesis. By that time the automatic scanner was well on the way, if not already working, but Sunden was quite insistent that he wanted us just to reproduce Donald's original equipment for his use, and that he was willing to pay whatever was needed to have this done.

By that time the costs of the project were escalating, and the chances of commercial recovery were still distant, so this approach was exceedingly welcome. We decided that we would make a hand-operated machine for Sunden, but that we would attempt to do it 'properly', and that if we succeeded this would be a prototype for a commercial machine. We did not want to frighten the customer away, but desperately needed to vindicate the project to our own higher management, and eventually decided on a price of all of 500 British pounds.

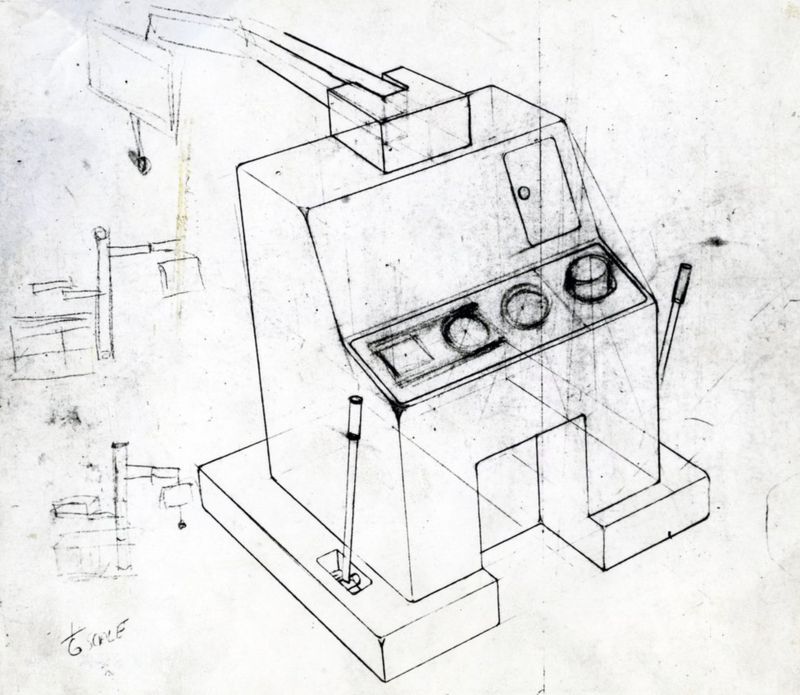

Young Dugald Cameron at the drawing table

Draft sketch of Dr. Sunden's machine

I designed a light-weight 'measuring frame', which was to be supported over the patient by an articulated arm and 'inverted-u-shaped' member, such that the measuring frame could be moved bodily in both longitudinal and transverse directions, and could be rotated both about a vertical and a horizontal pivot system. There was a chain operated parallel-motion device to control the orientation of the measuring frame, and keep it independent of the translational adjustments. The whole thing could rise and fall on a counterbalance system, contained within a substantial column. Dugald Cameron, later Head of the School of Design, Glasgow School of Art, co-operated in the design. He produced 'air-brush' drawings of the concept which were exceedingly useful for communicating what we wanted to others, and for soothing the customer as time passed, about why it was worth waiting for his machine!! However, at that time Cameron had barely finished his studies, and this was virtually his first real commission.

Another figure came into the story at that time in the person of Brian Fraser, who had established a reputation for himself as a practical designer in the field of marine instrumentation, and he took over the mechanical aspects of the job, allowing me to concentrate on the electronics.

Sunden's machine was delivered in late 1961 and with it he rapidly went on to confirm all of Donald's clinical findings, and to extend these in some directions, most notably we continued our policy of reducing ultrasonic output to the absolute minimum consistent with an adequate clinical result. This included reduction of the pulse repetition rate to 25/second, giving the characteristic 'spotty' appearance to Sunden's pictures.

I think this was a sensible approach, though perhaps overdone in this instance, and we looked somewhat askance at our transatlantic cousins, using vastly higher pulse rates, and so far as we could see, as much acoustic output as they could muster.

Sunden published his results, having secured his MD, and I think contributed very substantially to wider medical acceptance of the technique, particularly in Europe. His machine, unfortunately, fell into the hands of a scrap merchant.

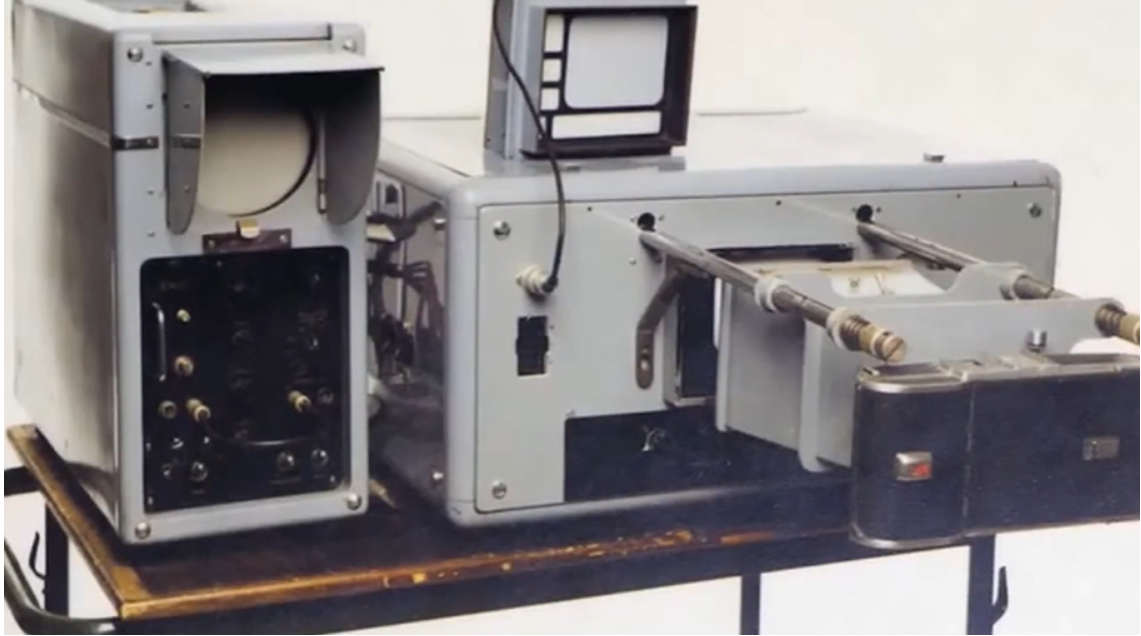

The Diasonograph

By 1961 I had a small group of engineers working on medical ultrasound. However there was much trouble in the company's industrial ultrasonic testing activity, based in Barkingside, in Essex. The work I had been involved in the early 'fifties' on semi- automatic ultrasonic testing techniques, had been developed further, and the company's sales people had sold a number of very ambitious automatic testing systems which were, frankly, a little beyond their capability to supply. This was resolved so far as the Barkingside factory was concerned, by transferring the whole lot to Glasgow in 1961! I and my handful of people became the nucleus of a team which was eventually built up to about 25 people, under the late Alex Rankin, the man I originally worked under on industrial ultrasound back in the early 'fifties'. Rankin died tragically in 1963, and I took over as department head.

Medical ultrasonics had to take a bit of a back seat for a time, but we did press on with the development of a production scanner, broadly based on the design supplied to Sunden. This was again a hand-operated machine with an X-Y measuring frame, supported on what turned out to be a rather massive gantry. However, we were selling into a market, we thought, accustomed to massive X-ray machines, and the gantry did give a degree of adjustment and control over the position of the scanning plane which I think was far superior to the early competitive machines.

We were also making A-scope instruments, mainly for industrial purposes, but we made a special version adapted for echoencephalography.

The question of names arose, and nobody could come up with anything very exciting. Eventually I suggested that we make up the word 'Diasonic' and use it as an adjective, so we could have a 'Diasonic scanner', and a 'Diasonic A-scope' etc. However, we ended up with 'Diasonoscope' to describe the A-scope instrument, and 'Diasonograph' to describe the scanner.

The trouble was that quite a few of our potential customers couldn't pronounce these jaw-breaking names. I've even heard unkind reference to the 'Dinosaur-o-graph'.

In the early 1960's Smiths progressively "moved in" on Kelvin & Hughes, and in about 1964 the Glasgow operation became the subject of an internal "take-over" by Smith's Aviation Division. Peter Turner was unceremoniously sacked, Bill Slater retired, and we found ourselves at the mercy of a bunch of American-management-style whiz kids.

In the early 1960's Smiths progressively "moved in" on Kelvin & Hughes, and in about 1964 the Glasgow operation became the subject of an internal "take-over" by Smith's Aviation Division. Peter Turner was unceremoniously sacked, Bill Slater retired, and we found ourselves at the mercy of a bunch of American-management-style whiz kids.

For the first time in my young life I found myself working for a younger man, though not for long because by that time I had found myself a new job as Chief Engineer of Honeywell's Medical Equipment Division in Hemel Hempstead. There I became involved with equipment for open-heart surgery, coronary care, prefabricated operating theatres etc., but no ultrasound. Brian Fraser took over from me, and presided over the deliveries of the first production Diasonographs. Two years later, in mid-1967, Smiths decided to close down the Glasgow factory.

This appears to have coincided with or possibly been related to a judgement by the US Supreme Court against Smiths and in favour of Automation on the question of the so-called "Firestone patents" on ultrasonic testing. As part of the settlement, Smiths undertook to withdraw both from the industrial and medical applications of ultrasound, and Automation acquired title to the collection of Smiths' patents on these subjects. This included the patents drawn in my own name as Inventor, and included the very basic one on two-dimensional ultrasonic scanning.

The position was not entirely clear-cut, because Smiths were able to sell the industrial ultrasound business to a Swedish concern, Essem Metotest, and the medical business to Nuclear Enterprises in Edinburgh.

Though by that time is was really nothing to do with me, I had taken it upon myself to go to see an Under-Secretary at the Ministry of Health, called Sam Davies, with the intention that if official decisions were to be made about what to do about medical ultrasound scanning, then they would at least be informed decisions. Ultimately, and after numerous false starts, the project and I both went to Nuclear Enterprises Ltd., in Edinburgh, where I was joined shortly after by Brian Fraser. To start with there it was a question of re-establishing the activity in its new home, and reassuring the customers that all was well. The instruments were re-established in manufacture, more-or-less in the form taken over. We began to sell, with help from the Ministry of Health, and before very long the stock taken over from Smiths was used up, and fresh manufacture had to begin.

However the electronics of the Diasonograph instrument were still valve-operated, and clearly this could not go on. About 1968 I began to go through a difficult personal patch, probably reacting to past domestic problems, and a very uncomfortable period with Honeywell, and for a time was fairly incapacitated.

Brian Fraser then became the main driving force behind the activity again. He re-vamped the mechanical design, though retaining the original measuring frame, and oversaw the redevelopment of the electronic system using semiconductor technology at the hands of a very gifted electronics engineer, Alan Cole.

The resulting "NE 4102 Diasonograph" became a very successful instrument, and was used in most British hospitals and many European ones. However, by this time I had once again moved on.

Time Warp

I became stuck in a sort of technological time warp, as a consequence of which I found myself developing a three-dimensional ultrasonic imaging system in the '70's which, with hindsight, had many of the attributes of what would now be called virtual reality. In the course of this I learned a good deal about the subjective, as well as the technical aspects of three-dimensional imaging, and developed an absorbing interest in what goes on in the eye-brain-tactile mechanisms of the observer.

Patents

3-D scanning finally came about largely as a matter of necessity imposed by patents. I was named as the inventor in the original Kelvin & Hughes patents on 2-D ultrasound contact scanning, which were pretty basic. However there was a long-running battle going on in the US courts between Smiths, and Automation Industries Inc of Denver, over the so-called "Firestone Patents" on industrial ultrasonic testing.

Smiths eventually lost the case in the US Supreme Court in the mid 'sixties, and as part of the settlement agreed to pull out of ultrasonics, and sell the Smiths ultrasonics patent portfolio to Automation. Kelvin & Hughes in Glasgow was shut down in 1967, but because of Ministry of Health pressure, the 2-D medical scanner line was preserved and sold off to Nuclear Enterprises in Edinburgh. They also received a "paid-up licence" under the "Brown Patents" as they became known, so that they could continue to make and sell the machines, but unfortunately nobody else in the UK shared that privilege.

I helped to get the business re-established within Nuclear Enterprises, but then moved on to a research job at Edinburgh University. I then wanted to go back into the ultrasound business, and by this time the new owners of the 2-D scanning patents were going round demanding royalties with menaces from everyone in the business.

I then found myself in the curious position of having to invent my way around my own basic patents. The only way I could see to do it was to invoke 3-D scanning. The words "....adapted to be moved in a plane" was the only weakness I could see in the generality of the original main claim. If I made a machine in which the probe was not constrained to move in a plane, then I was clear.

At the time there was a small company, Sonicaid Ltd, based at Bognor making fetal monitoring equipment, and very keen to get into medical imaging. We reached an agreement, and in late 1973 I took over a small factory unit in Livingston, near Edinburgh, and started building up a small team of people I'd known from the past, to develop a fully-featured 3-D medical scanning system.

"Real-time" scanning arrays were only just appearing, and so we started with a system based on a conventional single-transducer "probe", which could produce a highly-directional focused beam of very short ultrasonic pulses in the sub-millimetre wavelength range. We knew that if we wished to do so later on, we could replace it with a real-time array, provided we made provision for that in the basic design.

The fundamental concept was that if we knew where the probe was, and where it was pointing in 3-D space relative to a fixed set of axes, and if we also knew the velocity of sound and how long it took for a pulse to travel to and from a target; then we had the basic data needed to define that target's position in 3-D space. There was no need for two probes, or cross-bearings or anything else, - pulse-echo systems are intrinsically three-dimensional, provided one does not throw the data away !

DEVELOPMENT

The 3-D "Multiplanar" scanner development broke down into three main parts, each of which have their counterparts in VR. Firstly we needed a 3-D measuring system to track the probe and it's sound beam in 3-D space, in both position and orientation. Secondly we had to provide a display system which would present the 3-D data in some intelligible form. Thirdly we required a mechanism which interacted with the user so that he or she could modify the view they had of the synthetic 3-D environment we created.

There have been several attempts over the years to develop ultrasonic stereoscopic scanners, and we were certainly not the first. However the others didn't seem to get much further than one-off research projects, whereas we were, I think, the first to try to drive it all the way through to a marketable product.

MEASURING SYSTEM

We achieved the necessary freedom of probe movement by mounting the probe on gimbals on the end of a 4-foot "dipping-duck" counterbalanced boom. This was itself mounted on gimbals in the front of a measuring tank. A fine linkage mechanism transferred a mirror-image of all movements of the probe relative to the boom assembly, to a "wand", about the size of a match stick, inside the tank. In this way the probe could be moved around anywhere on the patient's skin, and pointed in any direction into the body, and the wand would reproduce these movements, in reverse, inside the tank. The tank was an oil-filled anechoic chamber, on three sides of which were fixed arrays of receiving transducer tiles . The wand supported two small acoustic emitters, ("beads") which were effectively omni-directional point sources of acoustic pulses. The inner bead corresponded, in scale, to the position of the probe face. The outer bead corresponded to a point on the probe axis about 15cm away from the face.

When the inner bead was pulsed the times of flight of the spherical wavefront to the three orthogonal plate receivers were converted into voltages representing the X, Y & Z positions of the probe face. In a similar way pulsing the outer bead produced a further three voltages. The differences between the first and second sets of voltages corresponded to the "directional cosines", - proportional to the components of the sound pulse velocity along the three axes. This relatively simple system thus gave us 6 signals, - 3 positional and 3 directional, - which when combined with time-of-flight and echo amplitude data, provided us with all we needed to drive the 3-D imaging system. I am sure we were by no means the only group to use a similar type of location system, - I know for example that Ray Brinker in St Louis used a similar system, but through air, to locate a hand-held transducer array on a patient, and there will doubtless have been others.

DISPLAY SYSTEM AND INTERACTIVE CONTROLS

The following describes the display arrangements as a series of "layers" of sophistication, as though they had been applied one after another. Of course it was not like that, but there was a kind of break point at one stage, when, after some water tank experiments, I came to the conclusion, - somewhat reluctantly, - that we would have to go all the way into stereoscopy.

Where I refer to the "display screen", we routinely used conventional electrostatic medium-persistence crt displays, variable-persistence storage displays, and scan-converters. Initially the scan converters were the Princeton analogue types, but later digital scan converters became available. Scan conversion had several advantages. The most obvious was that once the image was converted to raster-scan TV format, we could use all the available video display and recording technology. Until the advent of scan converters, the best grey-scale images were obtained by photographic integration from a conventional crt, - storage displays were poor by comparison. However the early analogue scan converters gave us quite pleasing grey-scale images directly, though I felt this was as much to do with image "softening" due to charge spreading in the storage matrix, than genuine grey-scale. Purpose-built 3-D displays like the Tektronix one were not yet available.

The first part of the display electronics generated three vectors representing the starting values, and components of the sound velocity along the primary co-ordinate axes of the system. Echo information was processed to compress the enormous dynamic range of received echoes into the limited grey scale available, while still preserving the definitive leading edges of pulses so far as humanly possible. It was then presented as brightness modulation of whatever display device was used.

If for example a simple crt display was used, then utilising the X and Y vectors as x and y timebases; and modulating the gun by echo information, would provide a "picture" of the patient's tissues as seen from a viewpoint along the remaining (Z) axis. In the same way any other pair of vectors could be used to present a picture from along the remaining axis. Variable viewpoint projection

In practice, instead of putting the three vectors directly into a display device, we first put them through a two-stage co-ordinate transformation network, with which we could rotate the viewpoint in azimuth and in elevation. This now very familiar computer graphics trick was then a bit unusual though by no means unknown . Nowadays it would be done digitally, but in the 'seventies we used a pair of double-gang analogue sine/cosine potentiometers and some operational amplifiers to do the necessary computation.

This enabled us to choose any viewpoint on the surface of an imaginary sphere surrounding the patient, from which to build up a three-dimensional "view" of the tissues.

View Control Unit

The two sin/cos pots were mounted in a little desk-top gizmo which we called the "view control unit" (VCU) which is easy to demonstrate but hard to describe, which provided the user with a moveable "window" with an arrow through it, which could be panned and tilted to enable him to choose the "line of sight" he wanted. The VCU could also be translated along three axes, driving linear encoders as is went, so defining the viewpoint position, in addition to the direction of view.

In this way the VCU performed part of the functions of a VR helmet, except that while the user could choose his viewpoint fairly intuitively, with some tactile feedback, it was by hand rather than by moving his head. Although helmet-mounted displays were already available for military purposes, they were out our reach, and we had to make do with console-mounted screens.

Viewing Field Truncation

Apart from controlling the viewpoint, the VCU had further controls within it to "gate" the echo signals, so that only those signals arising from a selected volume of space would be displayed. The viewable volume was defined as the space within six planes, two for each axis, equivalent to the walls of a box. In this way one could present all echoes from within a rectangular volume of tissue, or close it down to a thin layer to simulate a 2-dimensional scan.

"Range-gating" was also provided. This could be used, for example, to "peel off" the superficial layers of tissue to a selected depth below the skin surface.

Stereoscopy

So far, the above describes a variable-projection system, but one which only projects a particular monocular projection of the data onto a flat screen. This was as far as I had originally intended to go, because even then I was wary of user reaction to stereoscopy.

The original design objective was not to make "solid" pictures of the tissues. There are just so many echo signals returned from the tissues that one would run into a "white-out" very quickly, What we aimed to do was to be able to superimpose multiple conventional 2-D "cuts" on the same screen, to form a composite image in which we could see the relationships between the (sampled) tissue structures. We found we could do this quite effectively, so long as we chose an oblique viewpoint from which the individual scans did not overlap. If scans did overlap on screen, then there was no way of distinguishing foreground from background echo signals.

I ran some experiments with a prototype system, with a little plastic doll stuck in front of a bit of carpet tile in a bucket of water. This was an extreme example of the "overlapping" problem. I was so impressed with the way the image of the doll "jumped out" of the mass of echoes from the tile surface when viewed stereoscopically, and then disappeared completely when I shut one eye, that I realised that we just had to grasp the nettle of synthesised stereoscopic imaging. Stereoscopy was actually implemented very simply. We provided two views of the same data from viewpoints separated horizontally by something close to the intra-ocular distance. In this case the two images were displayed by means of alternate frame switching on the two halves of a split screen.

An optical wedge stereoscope with a central shield plate was built onto the various display screens, so that when the operator looked into the space "behind" the screen, he saw a three-dimensional spatial image. We found that these stereoscopes were most acceptable if they were "skeletal". There was a strong negative reaction to any kind of "hood" which prevented the user from also keeping an eye on what was going on round about him. Never put your customer's head in a box !

Perspective

The final level of processing simulated the effects of linear perspective, and removed the jarring artificiality which would have arisen if it were not provided. Analogue multiplier elements were employed to modulate the amplitude of displacements perpendicular to the mean viewing direction, in inverse proportion to the distance of the echoes away from the observer. In this way structures close to the observer would subtend larger angles than ones further away, but because of the size-constancy mechanisms of the brain, would appear to be the correct relative sizes.

IMPLEMENTATION

Detailed design began in early 1974, on what I regarded as a fairly stout shoe-string. I do not mean to be disrespectful in any way, but we were a small company, and it was clear to me that we were unlikely to get "a second bite at the cherry". It had, so far as humanly possible, to be right first time, and anything we were likely to need in the future had to have provision for it built in at the outset. It did not matter if things had to be added later, but we could not expect the luxury of being able to do a basic re-design in the immediately-foreseeable future to accommodate things which we had failed to make provision for.

I was convinced that sooner or later we would want to use coherent processing of some sort or other, - for example to extract Doppler from echo returns, or to use coherent demodulation for some of the semi-holographic imaging techniques then being exploited for synthetic aperture systems such as sideways-looking radar.

Consequently the whole system was run coherently from a crystal clock, which synchronised all pulse-generation and display functions. However much of the display system used analogue elements such as operational amplifiers and multipliers, and of course the signal-frequency system had to be largely analogue in nature, though coherent detection was available if we wished to use it.

RESULTS AND MARKET REACTION

The system worked quite remarkably well. As the operator scanned the transducer around, he or she could "see" the sound beam waving around in three-dimensional space, "lighting up" reflecting structures inside the body, rather like a wartime searchlight illuminating enemy aircraft.

There was a satisfying "interactivity" between the movements imposed on the probe, and what was observed in the display. The user could "explore" the structures he was interested in a very real and satisfying way. We could meet our original objective of building up composite scans involving many superimposed "slices" of tissue, and our machine was unique in being able to do it.

However the real pay-off came from a quite unexpected direction, and was to do with the constraints on resolution imposed by the physics involved.

By and large, the higher the frequency of the ultrasonic energy, - and so the shorter the wavelength, - the better the available resolution. However ultrasound is rapidly absorbed as it passes through tissue, and the shorter the wavelength the more rapidly this happens. There is a necessary trade-off between frequency (and hence resolution) and the range from which echo information can be obtained.

(WHY 3-D HELPS)

Unfortunately it is by no means as simple as that. The directionality of any radiating source is a function of the aperture/wavelength ratio. However out to a distance equal to the square of the aperture radius, divided by the wavelength, one is in the "Fresnel Zone", in which the distribution of sound energy is exceedingly complex, and the effective "beamwidth" approximates to the diameter of the source. Finally, the short pulses necessary for range resolution implies an extremely wide frequency spectrum, each component of which has its own directionality and Fresnel Zone. This has the effect of "smearing" all these otherwise calculable considerations over a wide range of wavelengths. One can also do a certain limited amount of beam shaping with acoustic lenses cemented to the transducer face.

What this all means is that obtaining the optimum resolution performance in an ultrasonic imaging system involves uneasy compromises between all sorts of conflicting factors, and comes close to being an art, rather than a science. Add to that the problems of compressing a dynamic range of echo responses in the order of at least 60db (probably nearer 100db) into the seven or so available grey levels in display devices while preserving as much of the pulse envelope data as possible, and one begins to realise that the designers "were living in interesting times".

From the user's point of view, - who is always looking to discern more and more detail, - it all means that he or she is usually working close to the achievable resolution of the system.

This is where the advantages of a genuinely three-dimensional system began to emerge. It appeared to have its greatest value in "making sense" of small structures which lay close to or below the otherwise achievable resolving power of the ultrasonic system. This is a difficult proposition to prove. Of course it did not actually enhance the "objective" resolution, which was determined by the usual factors such as bandwidth, wavelength, aperture etc. What it did seem to do was to enhance the operator's "understanding" of what he or she was looking at, and my best estimate was that it more-or-less doubled the "subjective" accessible resolution which the operator could use.

This has made me re-think how, and for what purpose, stereoscopy evolved in Nature. It is very much a "hard-wired" system, with split "wiring" to the retina, and all sorts of other major hardware components. Though different species vary in the extent of the stereoscopic field which they possess, stereoscopic vision is present in many creatures which have never really had much call for living in trees, or playing ball games. Though stereo vision does provide range-finding capability, I wonder if that may be a secondary, incidental benefit, rather then its prime purpose.